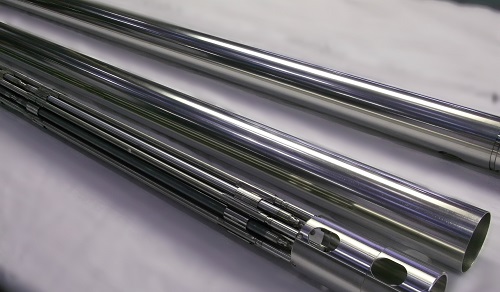

The Research Institute of Atomic Reactors in Dimitrovgrad, Ulyanovsk Region, has started the fourth irradiation cycle of fuel assemblies with VVER type fuel rods in the MIR research reactor, the reactor tests have been lasting since early 2019. These rods have four various combinations of cladding and fuel matrix materials. The fuel pellets were made either of traditional uranium dioxide, or uranium-molybdenum alloy with increased density and thermal conductivity. As the rod cladding material, zirconium alloy with a chromium coating or chromium-nickel alloy were used either.

On a parallel track, the new VVER and PWR roads with uranium disilicide fuel matrix have been loaded in the reactor core for irradiation. The technology of uranium disilicide pellets fabrication has been developed by the Bochvar Institute in Moscow, a research facility of TVEL Fuel Company, which is in charge of the Russian ATF project.

Uranium disilicide (U3Si2) has a number of advantages as a fuel matrix. First, it is high density and uranium content, which may enable introduction of longer fuel cycles without increasing the enrichment level. Second, it is high thermal conductivity and low heat capacity, which means less accumulated heat in the reactor core and lower temperature of the rod claddings. And third, the lower operating temperature may improve the performance characteristics of the fuel in general.

In addition to that, since September 2021, the first irradiation cycle of the VVER-1000 ATF fuel rods has been on the run at the Rostov NPP #2 commercial reactor. Each of the three TVS-2M design bundles contains 12 ATF lead test rods with innovative cladding, made either of chromium-nickel alloy, or a standard zirconium alloy cladding with chromium coating.

“Our ATF development and testing program is being accomplished on several parallel tracks with a system-based approach. It is not just about choosing the right combination of materials with the best post-irradiation results, but also about gradual introduction of these material in the “big power” – the high capacity commercial reactors. Thus, the first VVER-1000 lead test rods have only ATF cladding, but further on we may consider implementation of at least three various fuel matrix materials with all the necessary safety validations”, Alexander Ugryumov, Senior Vice President for Research and Development at TVEL Fuel Company, commented.

For reference:

ATF (Advanced Technology Fuel) is nuclear fuel resistant to severe beyond-design basis accidents at NPPs with the loss of coolant in the reactor. Even in case of heat removal failure in the core, ATF is supposed to keep its integrity for a long enough time without a zirconium-steam reaction inducing hydrogen release. ATF is of critical importance for further elevating the integral safety and reliability of nuclear power. Research, design and testing of the accident tolerant fuel in TVEL Fuel Company is provided and coordinated by the Bochvar High-Technology Scientific Research Institute of Inorganic Materials.